Higher Precision means even higher satisfaction.

Precise processing

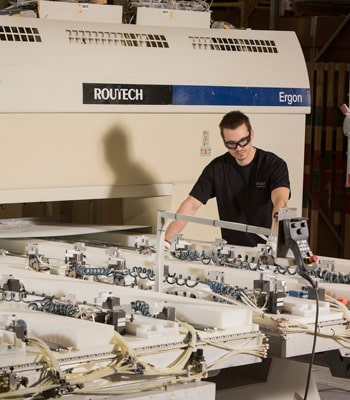

Our machining and fabrication processes incorporate statistical process control to assure every component part we manufacture meets customer specifications. Our machining and fabrication capabilities include multi-spindle drilling, mortising, routing, tenoning, planing, shaping and CNC woodcutting. Creating made-to-order parts using automated, top-of-line CNC milling machines, we can route even the most intricate shapes and sizes out of materials including solid woods, FSC® material, particle board, Agrifiber, LSL, LVL and others.

Why CNC Machining?

Computer Numerical Control, or CNC milling machines, are more precise than manual machining efforts, and the process can be repeated in exactly the same manner over and over again, quickly and efficiently.

Lexington’s CNC wood cutting processes use optimizing software to create a route, automatically cutting wood into different shapes and sizes — the exact dimensions the customer requested.

The precision possible with CNC machining allows us to route complex profiles and even three-dimensional shapes with extreme accuracy. It’s this high level of precision and repeatability that makes CNC machining the best choice for component parts manufacturing.

Customized

Manufacturing Solutions

Industry-Leading

Manufacturing Quality

Faster Time

To Market

Minneapolis

1330 115th Avenue NW

Minneapolis, MN 55448-3133

Telephone: (763) 754-9055

Fax: 763-754-9605